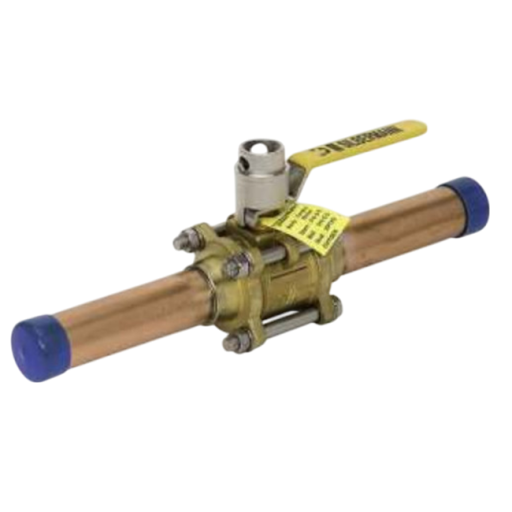

Cleaned for medical gas use and 100% hydrostatic tested, these 3 piece medical gas valves are designed to meet the NFPA 99c, ISO 7396-1 & G-01 standards.

Specifications

- Valve shall be 3 piece ball-type full bore design, with a bronze/ brass body, stainless steel ball, stem, bolts & nuts.

- Seat shall be Teflon (RPTFE) and seals Viton.

- Valves ½” to 2” shall have a minimum pressure rating of 4137 kpa (600 psi) wog.Valves 3” to 4” shall have a minimum pressure rating of 2758 kpa (400 psi) wog.

- Valve shall require only a quarter turn from fully open position to a fully closed position.

- Extensions stubs shall be K type with a minimum 150 mm long to allow brazing without damaging the valve seat and seals due to heat transfer during brazing operati

- Each valve shall be hydrostatically tested for leakages.

- Each valve shall be washed and degreased for medical gas use.

- Pipe stubs extensions shall be capped at both ends.

- The valves shall be supplied in sealed plastic bags, marked with “Oxygen” or “cleaned for oxygen use”, to prevent contamination prior to installation.

- Valves shall be Silbermann model SP150 or equivalent.

- All valves shall comply with NFPA 99, ISO 7396-1 & G-01 standards.

Medical Gas System Standards:

- NFPA99, EN ISO 7396-1 & G-01 requirements.

Silbermann’s Quality Management System:

- EN ISO 13485-2016

ISO 9001-2015. Medical Gas System Standards: